Wide sleepers are used in mainline and regional applications. The system is suitable for all gauges, for tilting technology, and for either freight or passenger traffic. As a result of its appealing design and ease of maintaining its surface, it is also well suited for tracks in train stations, and in urban areas. Wide concrete sleepers enable considerable reduction of loads on the ballast and the track substructure, since the larger support area ensures uniform distribution of pressure. The wide-sleeper solution furthermore lowers vibration values, lengthens maintenance intervals, and extends the service life of the track system. Wide-sleeper tracks enhance riding comfort, environmental compatibility, and the cost effectiveness of railway operations.

The advantages:

- Simple installation with conventional track-construction technology

- Constant quality and stability, and avoidance of continuous changes in the ballast substructure

- Up to 70% greater resistance to lateral shift, plus less settlement

- Significantly increased track availability

- Great safety from the large mass of the sleepers and from continuous bearing-surface support

- Simple vegetation control and minimal cleaning work, as a result of the closed surface of the track; no need for herbicides

- Systematic drainage of surface water and other liquids

- Considerably reduced emission of structure-borne noise into the soil foundation, owing to the greater mass of the sleepers

Wide sleepers are used in mainline and regional applications. The system is suitable for all gauges, for tilting technology, and for either freight or passenger traffic. As a result of its appealing design and ease of maintaining its surface, it is also well suited for tracks in train stations, and in urban areas. Wide concrete sleepers enable considerable reduction of loads on the ballast and the track substructure, since the larger support area ensures uniform distribution of pressure. The wide-sleeper solution furthermore lowers vibration values, lengthens maintenance intervals, and extends the service life of the track system. Wide-sleeper tracks enhance riding comfort, environmental compatibility, and the cost effectiveness of railway operations.

Trials conducted and experience gained

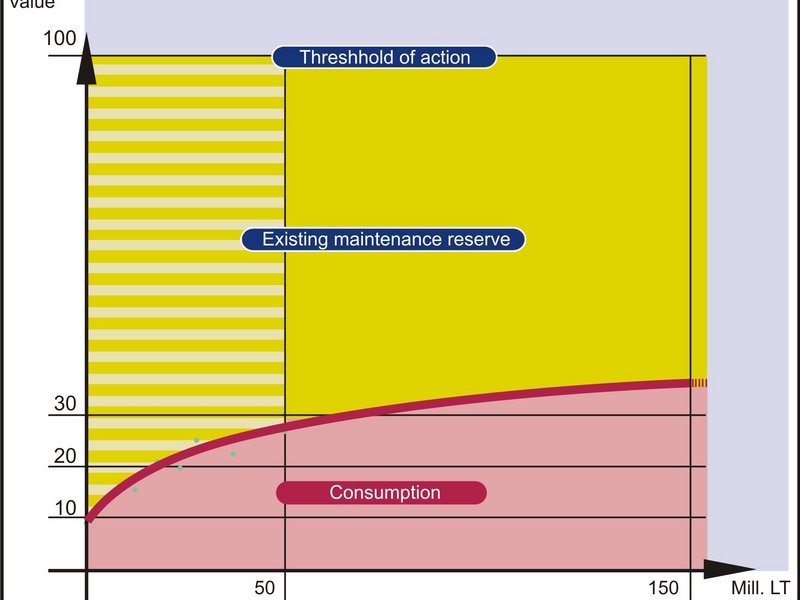

Wide-sleeper track has until now been installed within the contexts of a test-track section, and of a pilot project, on a track length of approx. 12 km. Both of these projects included the execution of extensive measuring programs. The trial section installed in 1996, near Waghäusel train station, in Germany, featured the following characteristics: extremely heavy rail traffic on the busy Rhine Valley line, alternating freight and passenger operations, v ≤ 160 km/h, and axle loads up to 22.5 metric tonnes. By now, the test section has carried live loads of approx. 150 million metric tonnes. Track positioning, measured at regular time intervals, has changed very little. The existing maintenance reserve is more than 50% with reference to the threshold of action (i.e., the in time point at which maintenance or replacement must take place).

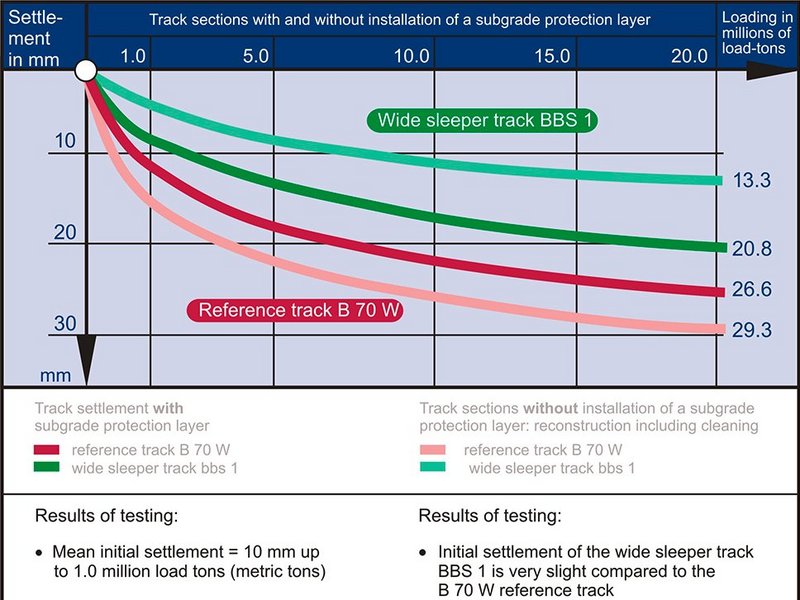

As part of double-track replacement, an additional pilot project has been conducted on the line section between Homburg (Saar) and Bexbach, in Germany. In this project, the wide-sleeper track (on the pilot-project track) was compared to a reference track executed as a standard version. The subgrade protection layer was also partially replaced in this project. This special trial constellation enabled obtaining interesting results for the settlement behaviour of the various track models. Test results revealed major advantages for the wide-sleeper track, even without replacement of the track substructure.

Measurements conducted on these long-term trials after loading of 20 million tonnes have clearly shown that the settlement of the wide-sleeper track is only half as great as that of the reference track. Several measurements have shown that changes in track positioning have been very slight. On track not including the transition sections, there is still very large reserve remaining for track wear, after total loading of approx. 150 million tonnes. Maintenance work has not until now been necessary. RAILONE is of course continuing to work on optimization of the system – beginning with sleeper manufacture and extending to tamping technology.

Technical data BBS 1

| Permissible axle load | 25 metric tonnes |

| Maximum speed | 160 km/h |

| Concrete grades | C 50/60 |

| Concrete grades | 230 I |

| Weight (without rail fastenings) | 560 kg |

| Length | 2400 mm |

| Width | 570 mm |

| Sleeper height | 233 mm |

| Height of rail-seat centre | 214 mm |

| High of sleeper centre | 225 mm |

| Supporting-surface area (total) | 13670 cm² |

| Standard application cases | Main-track sleeper |