Ballastless track system GETRAC® – Asphalt in top form

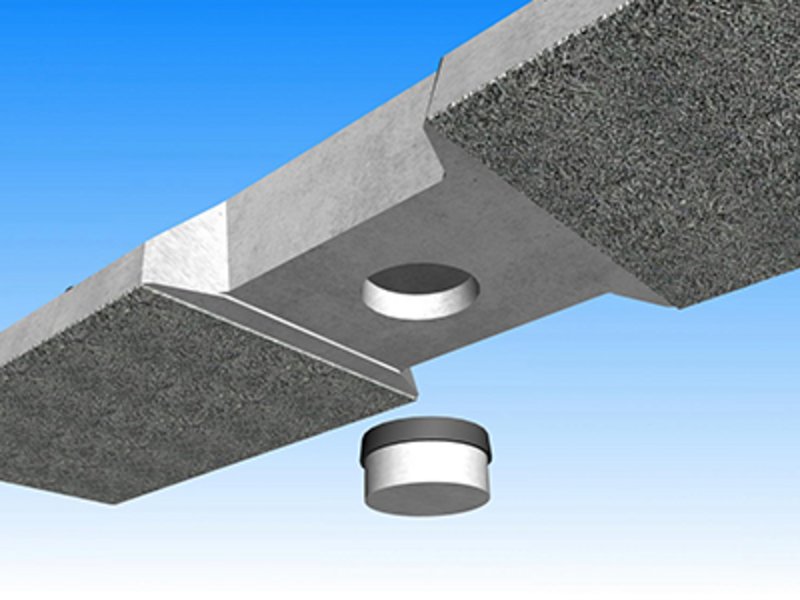

The GETRAC® systems offer all the advantages of a ballastless system – and are especially fast and uncomplicated in installation. A precondition, however, is highly developed asphalt technology – and we at RAILONE are quite proud of our engineering expertise here. The chief characteristic of GETRAC® track systems consists of an asphalt supporting layer on which concrete sleepers directly rest. The sleepers are elastically connected to the asphalt layer by special concrete anchor blocks, which transfer the horizontal forces from the track span to the supporting layer. A major advantage of this product is its fast and simple installation procedure with conventional track-laying technology, and with high daily track-laying output. The GETRAC® A1 system variation has become well known in our segment over the past few years, for its outstanding operational characteristics. The GETRAC® A3 ballastless track system is the newest and highest-performance product in the GETRAC® line. The wide sleepers, an intrinsic part of this system, reduce track installation height: which makes it especially effective for tunnel installations.

In 2004, the German Federal Bureau of Railways (EBA) provided official approvals, without speed limitation, for various track innovations in the form of GETRAC® model variations. This approval accordingly signifies clearance of GETRAC® for high-speed track applications as well.

The advantages:

- Constant track geometry, by application of rubber supports to provide elastic bonding of the track panel to the asphalt

- Short construction time

- Capability of using conventional road and track-construction equipment

- High degree of mechanization and small number of work steps in laying the track span

- Pre-assembly of the anchor blocks and the rail-fastening elements in the production plant

- Long life cycle with little maintenance

- Possibility of rail cant greater than 180 mm

- Great stability

- Suitability for both turnout tracks as well as main tracks

- Unimpeded drainage of rainwater and other precipitation

- Fast availability of the track after repairs